A new method of electrolytic coating of materials a thin layer of a substance has been developed at the Jagiellonian University. The innovation can be implemented on an industrial scale. What is important is that using it requires only a minimal amount of chemical materials and, additionally, its properties may contribute to a faster development of 3rd generation solar cells. The method can be used to cover different types of materials with layers that are only a few nanometres thick.

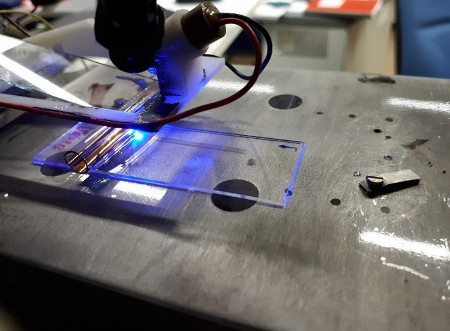

The technology developed at the Jagiellonian University by Prof. Jakub Rysz opens up new possibilities in the area of electrodeposition, as it allows the use of electrolysis without the necessity to dip the coated objects in solutions. It also provides novel opportunities regarding both the selection of coated materials and substances with which they are coated. The method makes it possible to manage the work of electrodes in such a way that coating practically resembles printing. This allows the creation of specific images, lines or patterns, as well as precise adjustment of the thickness of the layer covering the given material.

Minimal use of electrolytes: an environmentally friendly electrolysis

Electrodeposition is a process of coating various types of surfaces with a thin layer of a specific substance by means of chemical reactions. This allows protecting materials from corrosion, obtaining surfaces with desired electrical conductivity properties, and changing the aesthetic features of materials.

Unfortunately, the electrolytic deposition methods used to date consume a large amount of resources, which makes them both expensive and environmentally unfriendly. The team of JU researchers has worked out a game-changing method, enabling electrodeposition with the use of electrolytes in so small amounts that their cost becomes negligible.

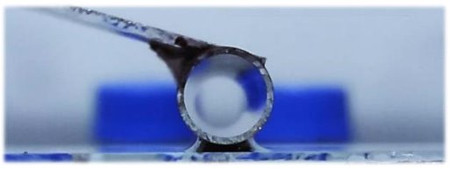

Movable Meniscus

What is the discovery about? A small amount of electrolyte is introduced between the coated surface and the head, placed closer than one millimetre to it. The electrolyte forms a meniscus no wider than a few millimetres, so that the liquid can fill the space between the head (with electrodes) and the surface. What is important is that the meniscus and the head can be moved on the coated surface during the electrodeposition process. The control system is supported by electrolyte dispensers and suction pumps working within the head. This allows the use of a minimal amount of the solution, as it remains in the head operation zone, on a relatively small surface. What is more, the electrolyte can be replenished or replaced during the work of the electrodes, which means that the whole operation can be done on larger surfaces.

Novel properties

Using a movable meniscus on the coated surface and a movable head with electrodes allows better control of the process, making it possible to create new patterns from the material applied to the surface as well as decide on the thickness of its layer.

The developed method can also be enhanced with photodeposition using laser light beams, which allows the coating of surfaces made of non-conductive materials.

Broad application prospects

The developed method has a potential to be broadly applied in industry, as it can be used for coating a wide variety of materials with a wide range of substances. In the near future it may be used, for instance, to produce photo catalysers for large surfaces, specialist panes as well as thin and elastic solar cells, and to coat surfaces with precious metals. The scientists also think that it will find use in such future technologies as smart films and other materials covered with microsensors.

At the moment, the Jagiellonian University is engaged in developing cooperation with technological partners who will implement the newly developed method directly in their own products and on their own production lines.